CNC mill-flip centers are available in two configurations – vertical and horizontal. The vertical configuration is taken into account more secure a result of the influence of gravity over the setup.

CNC machining in the automotive industry is likewise helpful for developing one particular-off custom parts. The creation of varied replacement parts is additionally attainable with CNC. It is because the turnaround situations are quick, and there is no bare minimum essential section quantity.

The Power sector is broad, with subsectors such as the oil and gasoline industry. As being a issue of point, the Vitality industry remains to be in The expansion stage Using the increase of eco-friendly Electrical power and renewable Vitality sources. CNC could be the supporting pillar for making tools and equipment across the energy sector.

The aerospace industry has a long-shared heritage with CNC machining. The machining of metal aircraft components takes place at the very best amount of precision.

Other than the transferring headstock, a sliding manual bush moves along the longitudinal axis of the workpiece. The guideline bush supplies aid to the workpiece for top-precision machining.

CNC mill turning centers, also known as CNC mill-convert machines, Mix precision milling and turning processes. Milling and turning have normally been accomplished on individual CNC machines. Nevertheless, combining them into just one CNC machine can substantially simplify the manufacturing process.

CNC milling can be a subtractive manufacturing course of action that utilizes rotary cutters to eliminate material from your workpiece. The course, angle, force, and cutting tool speed could vary to build distinctive cutting consequences.

Powder coating: The plastic powder is adsorbed into the area in the workpiece by electrostatic spraying to type a powdery coating, and after that the powder layer is cured by heating and baking to level it right into get more info a uniform movie layer. It will likely be used for physical appearance parts, and a range of hues is on the market.

But really wonderful capabilities and restricted tolerances are tougher to realize manually, and this is where a computer-controlled procedure next a electronic blueprint actually arrives into its individual.

Carbon Fiber—Composites and Glass Fibre can both equally be machined for applications that require lightweight but powerful Homes, for instance aerospace and sporting merchandise manufacturing.

CNC machining inside the Health care and health-related industry is used for manufacturing professional medical materials and quick tooling to make dies for injection molding. Then, the injection molding course of action provides equipment like encounter masks.

A CNC machine replaces human labor with Computer system numerical Handle systems and gets rid of the human error chance factor involved in the cutting processes. Workers is often transferred to a lot more skill-intense roles for example CNC design and style functions.

The meals and beverage industries aren’t the main believed that concerns mind when thinking about CNC machining. On the other hand, these industries depend greatly on CNC in numerous places.

As we method the 2030s, the die and mold industry will take advantage of additional enhancements in multi-axis machining and significant-pace CNC technology.

Anna Chlumsky Then & Now!

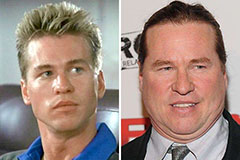

Anna Chlumsky Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!